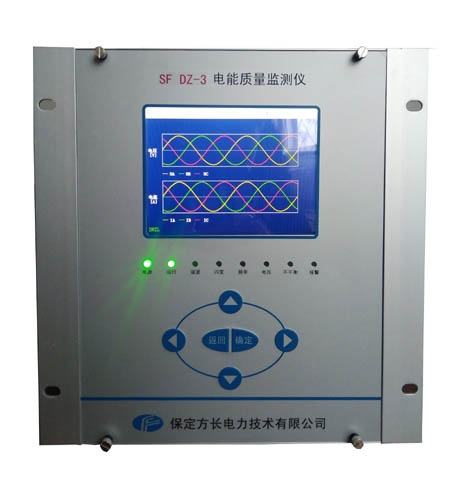

Power quality monitoringdeviceIt is an important device that can be used to monitor and analyze power quality issues in power systems, while assisting engineers in fault diagnosis and maintenance work. However, even high-end power quality monitoring devices may malfunction and require timely resolution. Below, we will introduce common troubleshooting methods for power quality monitoring devices in factories.

1. The power quality monitoring device cannot start

If the power quality monitoring device cannot start, it is necessary to first check whether the power supply is connected and connected, and whether there is power supply current. Secondly, it is necessary to check whether the switch and fault indicator light of the equipment itself are in normal state. If there are issues such as reverse power failure or voltage jump during equipment operation, it is necessary to check for poor circuit contact, low or high power supply voltage.

2. Inaccurate data

If the data displayed by the power quality monitoring device is inaccurate, it is necessary to first confirm whether various sensors and monitoring instruments are correctly connected. In addition, if there are fluctuations in power supply voltage and current changes, it may also lead to inaccurate data. In this case, repair and calibration are required.

3. Interface issues

If there are issues with the device interface, such as the USB port not being able to connect properly, it is necessary to check whether the interface has fallen off and whether dust has accumulated. If the problem persists, you can consider replacing the equipment or contacting a professional for maintenance and repair.

4. Software issues

Power quality monitoring devices are usually equipped with professional software that can record and analyze monitoring data. If the software fails to execute as expected, it is necessary to first confirm whether the software is installed correctly and maintain a newer version. Secondly, it is necessary to check if the computer configuration is sufficient and uninstall unnecessary programs to free up memory and hard disk space.

In summary, for troubleshooting the power quality monitoring device in the factory, a system inspection is required. Before replacing and repairing equipment, it is recommended to contact technical personnel to ensure that the performance and monitoring accuracy of the equipment reach optimal levels.

![]() National ordering hotline:fifteen billion eight hundred and three million one hundred and twenty-five thousand five hundred and sixty-five

National ordering hotline:fifteen billion eight hundred and three million one hundred and twenty-five thousand five hundred and sixty-five