On August 13, 2016, the G79 high-speed train from Beijing West to Shenzhen North Station experienced a power outage, trapping thousands of people in carriages at 40+℃ for nearly 2 hours. Many children and elderly people experienced discomfort and dehydration. The stable operation of high-speed rail is closely related to the power quality of its power grid, and how to ensure the power quality of high-speed rail power grid has become a hot topic of discussion at present.

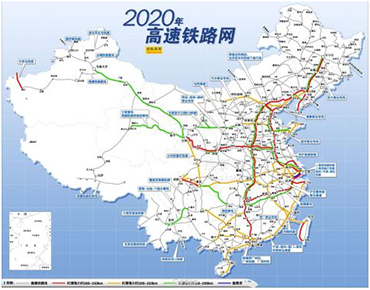

Figure 1 2020 Map Planning Map

By 2020, China will build over 16000 kilometers of high-speed railways, forming a fast railway network with "four vertical and four horizontal" high-speed railways as the main framework. Now, high-speed railways can operate at speeds of 300km/h and the call for speed increases to 350km/h.

The stable operation of high-speed rail is closely related to the power quality of the high-speed rail power grid, and power quality issues can lead to power grid failures and train power equipment failures. To explore the impact of power quality issues in high-speed rail power grids on high-speed rail trains, we must understand the power supply and driving principles of high-speed rail.

High speed railway traction power supply system

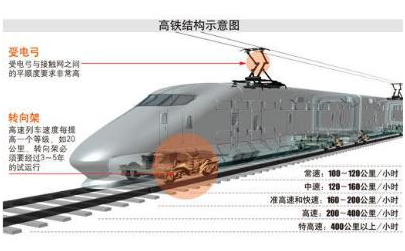

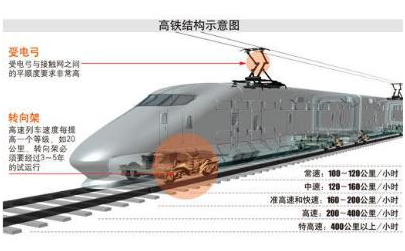

Figure 2 Schematic diagram of high-speed railway structure

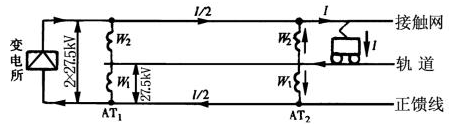

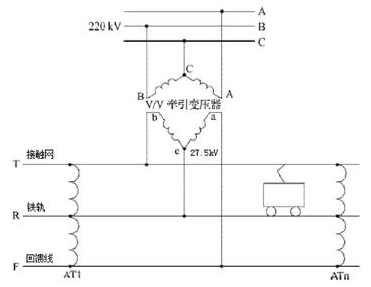

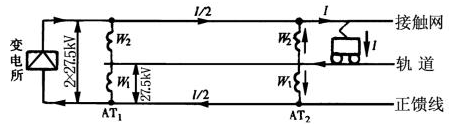

High speed trains can run by relying on the traction power supply system to provide electricity for high-speed trains. The traction power supply methods for electrified railways mainly include BT (suction transformer) power supply, AT (autotransformer) power supply, and TR direct power supply. Due to the high power and traction current of high-speed railways, AT power supply with strong power transmission capacity is generally adopted. A typical AT power supply system is shown in Figure 3.

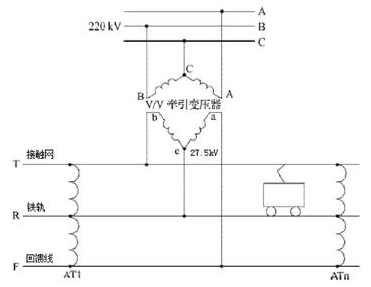

Figure 3 Typical AT power supply system

The power supply system mainly consists of traction substations (substations), autotransformers AT, contact network T, feedback line F, railway track R, and high-speed trains. The basic principle is that the traction substation provides power for the entire traction system, and the current flows out from the traction substation. It provides electrical energy to the high-speed train through the contact network, and then flows back to the traction substation through the feedback line. The working principle of the AT power supply method is shown in Figure 4.

Figure 4 Working principle diagram of AT

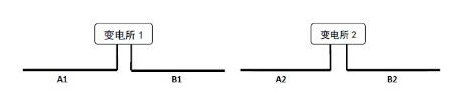

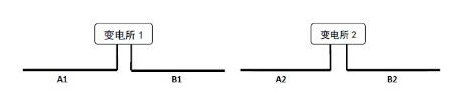

The power supply of high-speed railways is divided according to "power supply sections", with an average of tens of kilometers per seat. Each substation extends two power supply branches to provide currents of different phases. When the train passes through the "power supply section" of two substations, it successively passes through four power supply branches A1-B1-A2-B2. To ensure power supply, the structural design of electrical insulation (isolation) is adopted between each power supply branch, so there will be no short circuit between each power supply branch. The operation from one power supply branch to another is instantaneous. The schematic diagram of the power supply section is shown in Figure 5.

Figure 5 Schematic diagram of power supply section

High speed rail driving principle

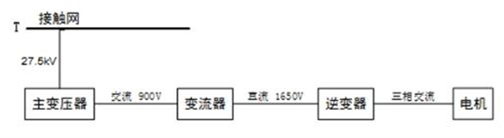

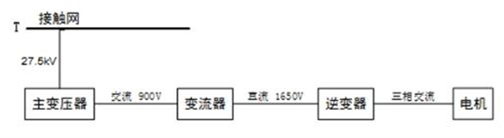

The traction power supply system provides power for high-speed trains, which rely on electricity to obtain power. Figure 6 is a schematic diagram of the driving principle of high-speed trains. The basic principle is that high-speed trains retrieve high-voltage AC power back into the train through contact between the pantograph and the contact network, and then convert it into DC through a transformer to reduce voltage and a four quadrant rectifier. After being converted into three-phase AC power with adjustable amplitude and frequency regulation through an inverter, it is input into a three-phase asynchronous/synchronous traction motor, which drives the wheels to run through the transmission system.

Figure 6 Schematic diagram of high-speed rail drive

Monitoring and Analysis of High Speed Rail Power Quality

High speed rail is a special type of high-power single-phase load. For three-phase symmetrical power systems, the traction load of high-speed rail has characteristics such as volatility, nonlinearity, and asymmetry.

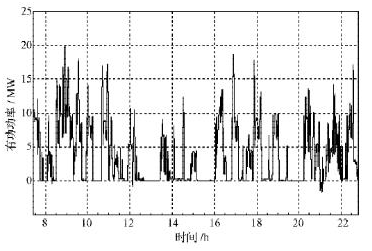

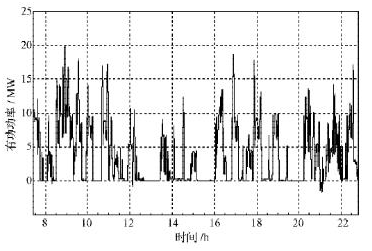

1. Load fluctuations and impacts

The acceleration, coasting, braking, and other factors of a train during operation can cause fluctuations in the load of the traction substation, especially when the train changes from one power supply branch to another, the instantaneous load fluctuations and impacts caused are very huge. The huge load fluctuations and impacts can cause abnormal fluctuations in the grid voltage. Figure 5 shows the changes in active power of high-speed railway traction substations within 24 hours, indicating significant load fluctuations and impacts.

Figure 7 Active Power Curve of Traction Substation

2. Nonlinear

From the driving principle of high-speed rail, it can be seen that high-speed rail adopts AC-DC-AC PWM converter technology, which converts the power frequency AC power through rectification and inversion into three-phase AC power with adjustable amplitude and frequency modulation to supply traction motors. This is a nonlinear process that inevitably generates a large amount of harmonics. In addition, the entire train power supply also needs to supply non-linear loads such as air conditioning and lighting inside the train, which will also generate a large amount of harmonics.

3. Asymmetry

The high-speed railway adopts a single-phase power supply system, and the load of the two power supply branches of the traction network cannot be consistent. Therefore, for the three-phase power grid, it belongs to asymmetric load, which will generate negative sequence current and cause three-phase imbalance in the external power grid of the traction substation.

High speed railway power quality hazards

Figure 8 High speed railway in operation

The harmonics, negative sequence components, and voltage fluctuations generated by high-speed rail during operation have a serious impact on the reliability of the high-speed rail power system. The power pollution of the high-speed rail power grid mainly has the following impacts on the high-speed rail power system:

Impact on the reliability of the power grid: A large number of high order harmonics generated by high-speed train operation are injected into the traction substation through traction transformers, introduced into the power system, and superimposed with the negative sequence source generated by the "background load" of the system, causing serious amplification of the 3rd and 5th harmonics in the internal power grid during resonance, leading to power grid faults;

Impact on the stable operation of power equipment: The harmonics and negative sequence components generated by high-speed railway traction loads can cause equipment damage, reduce equipment life or efficiency, and even cause work errors or performance degradation to equipment such as computers, communication, and power system relay protection devices. This can lead to skip level tripping and expand the accident or lead to main transformer and line tripping.

It can be seen that electric energy pollution in the high-speed rail power grid not only affects the stability of the railway's own small local power grid, but also affects the external power grid through traction substations. Whether it is the impact on one's own power grid or external power grid, it will threaten the stability of high-speed rail operation.

High speed railway power quality control

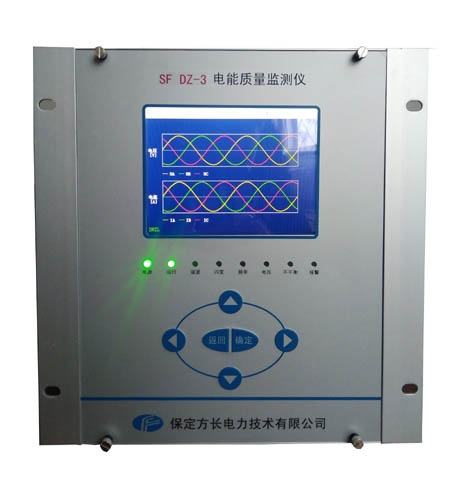

The reliability of the high-speed railway power system determines the reliability of high-speed train operation. Therefore, it is particularly important to monitor and manage the power quality of high-speed rail power grids. The traction substations of high-speed rail are independent of each other, and the power supply branches are also isolated from each other. Therefore, monitoring the power quality of the high-speed rail grid requires online monitoring of each power supply branch, which is then summarized to the backend host to achieve real-time monitoring of the entire high-speed rail grid.

Figure 9 High speed railway power grid

![]() National ordering hotline:fifteen billion eight hundred and three million one hundred and twenty-five thousand five hundred and sixty-five

National ordering hotline:fifteen billion eight hundred and three million one hundred and twenty-five thousand five hundred and sixty-five